Pass Every Safety Inspection

Without Rewiring

On offshore platforms, the wrong electrical connector isn’t just a maintenance concern — it’s a fire risk, shutdown trigger, or compliance violation.

That’s why Manning Electric standardized on the JOWO 8819, an ATEX certified electrical connector for hazardous marine environments.

In the words of their lead engineer:

“The client’s safety team didn’t just approve the 8819 — they asked us to spec it into future systems.”

Explosion-Proof Zone

Are Everywhere Offshore

Hazardous doesn’t just mean flammable gas — it means every exposed wire matters.

On oil rigs, FPSOs, and processing platforms, any area where vapor or pressure builds up is classified as Zone 1 or Zone 2 — requiring ATEX/IECEx compliant electrical hardware.

Most commercial connectors are:

✔️ Not explosion-proof

✔️ Built with poor sealing or no strain relief

✔️ Difficult to inspect

✔️ Unapproved for Class I Div 1 or Zone 1 areas

Failures or shortcuts here aren’t just expensive — they’re dangerous. And inspectors know where to look first: connectors.

Electrical Compliance Is No Longer Optional

Inspections are stricter. Certification expectations are rising.

The latest trend in offshore engineering isn’t more power — it’s more control, more data, and more compliance.

Designers and contractors are under pressure to:

• Use ATEX certified electrical connectors in hazardous zones

• Reduce maintenance costs by eliminating potting compounds

• Speed up inspection sign-offs with modular, labeled components

• Prevent connector failure from saltwater, vibration, or UV exposure

Upgrading to fully certified, ruggedized connectors is the fastest way to improve safety compliance without slowing down installs.

Know Your ATEX Ratings Before You Install

Don't guess — spec the connector that’s built for the zone.

Use this quick checklist before any offshore or nearshore hazardous area install:

☑️ Is the connector certified for ATEX Zone 1 or IECEx equivalent?

☑️ Rated IP68 or better?

☑️ Can it be disconnected and serviced without compromising its seal?

☑️ Uses corrosion-proof housing and elastomer seals?

☑️ Designed to avoid sparking or arc faults under load?

Download the full Offshore Hazardous Zone Connector Guide — free PDF.

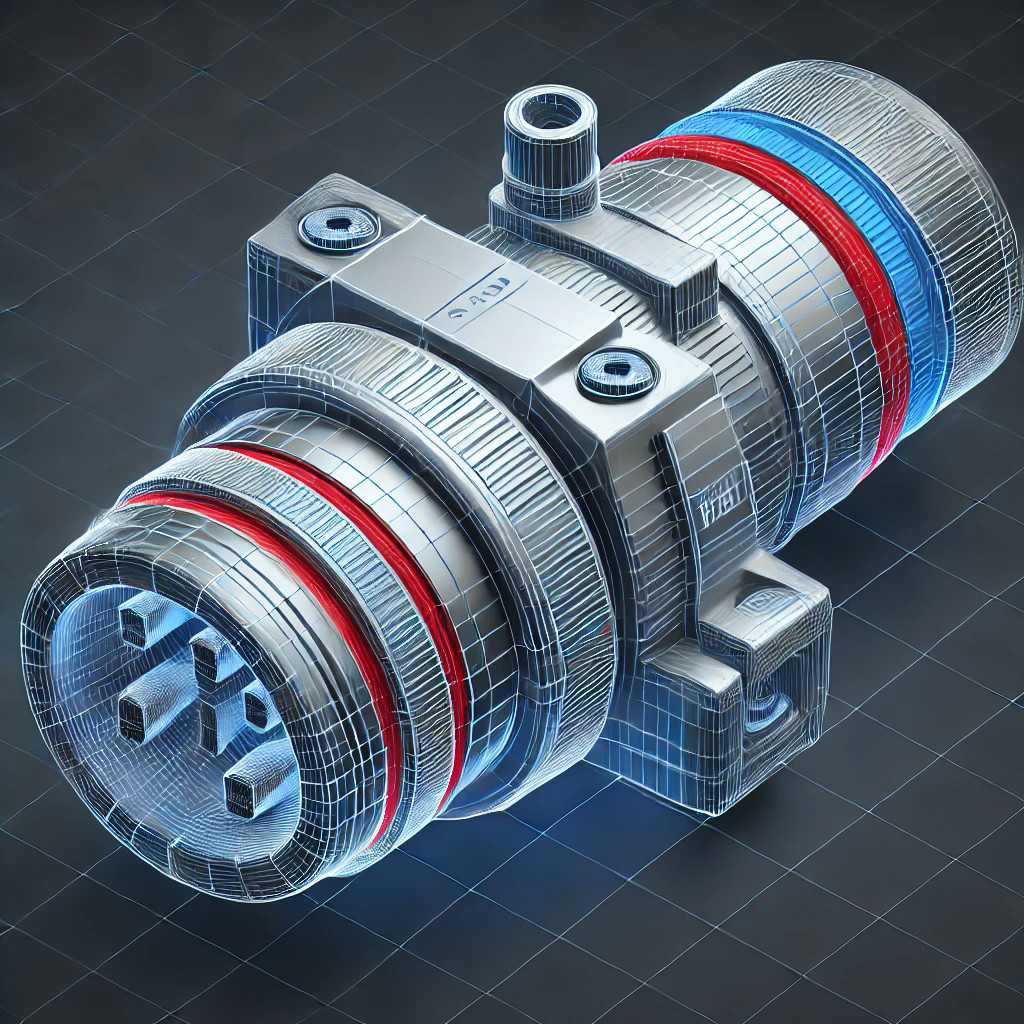

JOWO 8819

Offshore-Grade, ATEX-Approved

Manning Electric used it once — now they spec it by default.

Texas Electrical Connectors supplies the JOWO 8819 Series, purpose-built for use in hazardous marine environments. These connectors are:

✅️ ATEX & IECEx certified

✅️ Rated for use in Zone 1 / Zone 2 environments

✅️ Fully sealed to 300m (open-face pressure: 30 bar)

✅️ Operable without potting or resin

✅️ Designed with push-pull locking, strain relief, and modular backshells

Manning Electric used these connectors to upgrade a series of wellhead control panels and lighting circuits on an offshore gas platform.

“The 8819 series let us finish the job faster, pass inspection, and reduce risk. We’re not going back to legacy potted designs.” – Lead Engineer, Manning Electric LLC

Safety Officers Approve

From platform operators to compliance teams — the reviews are in.

✅ Used in hazardous zone installs across offshore Gulf platforms

✅ Rated for oil/gas, chemical, and marine fuel tank environments

✅ Trusted by Chevron, Dolphin Agencies, Summit Electric, Manning Electric

✅️ Stocked and shipping from Texas — $1000 off U.S. orders

Your connector is the first thing inspectors check — give them something to check off.

Whether you're wiring control panels or safety lighting, using ATEX certified electrical connectors for hazardous marine environments is no longer optional — it’s required.

The JOWO 8819 makes that compliance fast, simple, and affordable — and keeps your crew safer in the process.

One connector. Zero compromise.

🔹 Claim $1000 Free USA Shipping

🔹 Download the White Paper: Hazardous Zone Wiring Guide