From Constant Replacements

To Years of Confidence

Retrofitting an aging patrol boat fleet with new electronics is tough. But when connectors corrode faster than you can replace them, it becomes a never-ending money pit.

That’s exactly the problem Summit Electric was facing — until they standardized on a corrosion resistant shipboard connector designed to outlast traditional marine plugs by years. The upgrade? The JOWO 8819 Series, engineered for wet environments, rough handling, and deck-level durability.

Saltwater and Vibration

Are Connectors’ Worst Enemies

If you’ve ever pulled apart a corroded connector mid-mission, you already know: it’s not just a maintenance issue — it’s a liability.

Shipboard environments are brutal:

• Constant salt spray

• Daily hose-downs

• Wide temperature swings

• Nonstop vibration from engines and sea state

Standard connectors — even those marked “marine-grade” — often use low-quality plating, poor seals, or potting techniques that fail after 6–12 months in real-world use.

The result?

✔️ Broken lighting circuits

✔️ Faulty sensors

✔️ Emergency repair delays

✔️ Missed patrols or failed inspections

Retrofits Demand Higher Standards

Outdated connectors don’t belong in modern electronics suites.

Across both commercial and military vessel programs, fleets are undergoing critical refits to support:

✔️ Digital comms

✔️ Smart sensors

✔️ Surveillance systems

✔️ Remote diagnostics

These systems require rock-solid electrical connectivity and easy-to-service components.

That means:

• Push-pull couplers to speed up installs

• No epoxy potting, so connectors can be re-terminated on deck

• IP68 sealing for real waterproofing

• ATEX/IECEx certifications for safety near fuel lines and battery banks

Don’t Let a $40 Connector

Kill a $400,000 Upgrade

Retrofitting? Here’s what to look for in your shipboard connectors.

☑️ Can it handle long-term saltwater exposure?

☑️ Rated IP68 or higher?

☑️ Does it include modular options for 4 or 7-pin layouts?

☑️ Built for frequent mating cycles without seal wear?

☑️ Uses corrosion-resistant plating and elastomer seals?

Most importantly: can your electricians assemble and install it with no special tools or potting?

Download our whitepaper to access a full Connector Retrofit Checklist and project budget guide.

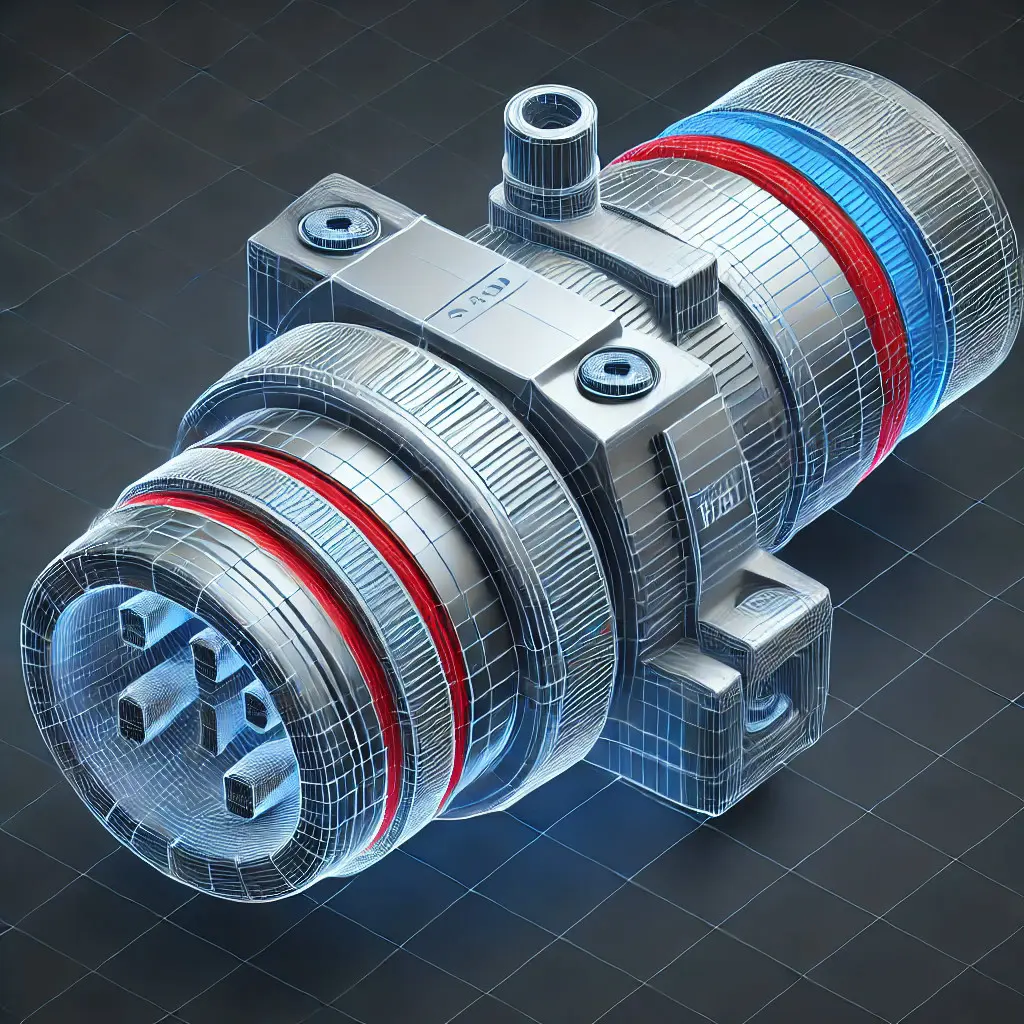

JOWO 8819 Series

Fleet Ready, Field-Proven

Summit Electric’s choice for their multi-vessel patrol boat refit? One connector line: JOWO 8819.

Texas Electrical Connectors delivered a bulk order of 8819 units to Summit Electric to outfit power and sensor lines aboard a 6-vessel patrol fleet. Installation crews completed field assembly with basic crimp tools — no epoxies or delays.

Since install, they've reported:

✅️ Zero failures

✅️ Faster install timelines

✅️ Easier field replacements

✅️ Fewer calls from the client

✅️ JOWO 8819 features include:

✅️ Glass-reinforced polymer housing (UV/saltwater proof)

✅️ Elastomeric seals rated to 300m depth

✅️ Push-pull coupling with locking

✅️ IP68 / 30 bar open-face rating

✅️ATEX certified for flammable compartments

✅️ No potting or curing time

“From a contractor’s perspective, using a high-spec connector like the JOWO 8819 makes our life easier. Our electricians crimped and assembled them on-site with ease.” — Project Engineer, Summit Electric

Retrofitting for Reliability

This isn't just about better parts — it’s about smarter installs and lower lifetime cost.

✅ In use by Summit Electric, Manning Electric, Chevron, and others

✅ Meets shipboard retrofit specs for defense and commercial marine

✅️ Ships direct from Texas with $1000 free U.S. shipping

Choosing the wrong connector can make a million-dollar retrofit feel like a downgrade.

If your shipboard systems rely on waterproof plugs, corrosion resistance isn’t optional — it’s mission-critical.

By standardizing on connectors built for service life, your upgrades stay operational longer and your crews stay focused on what matters.

Don’t just install — upgrade

🔹 Claim $1000 Free USA Shipping

🔹 Download the Retrofit Connector Whitepaper