Built to Survive

The Deep

What if your subsea connector could be uncoupled at 300 meters underwater and stay bone dry?

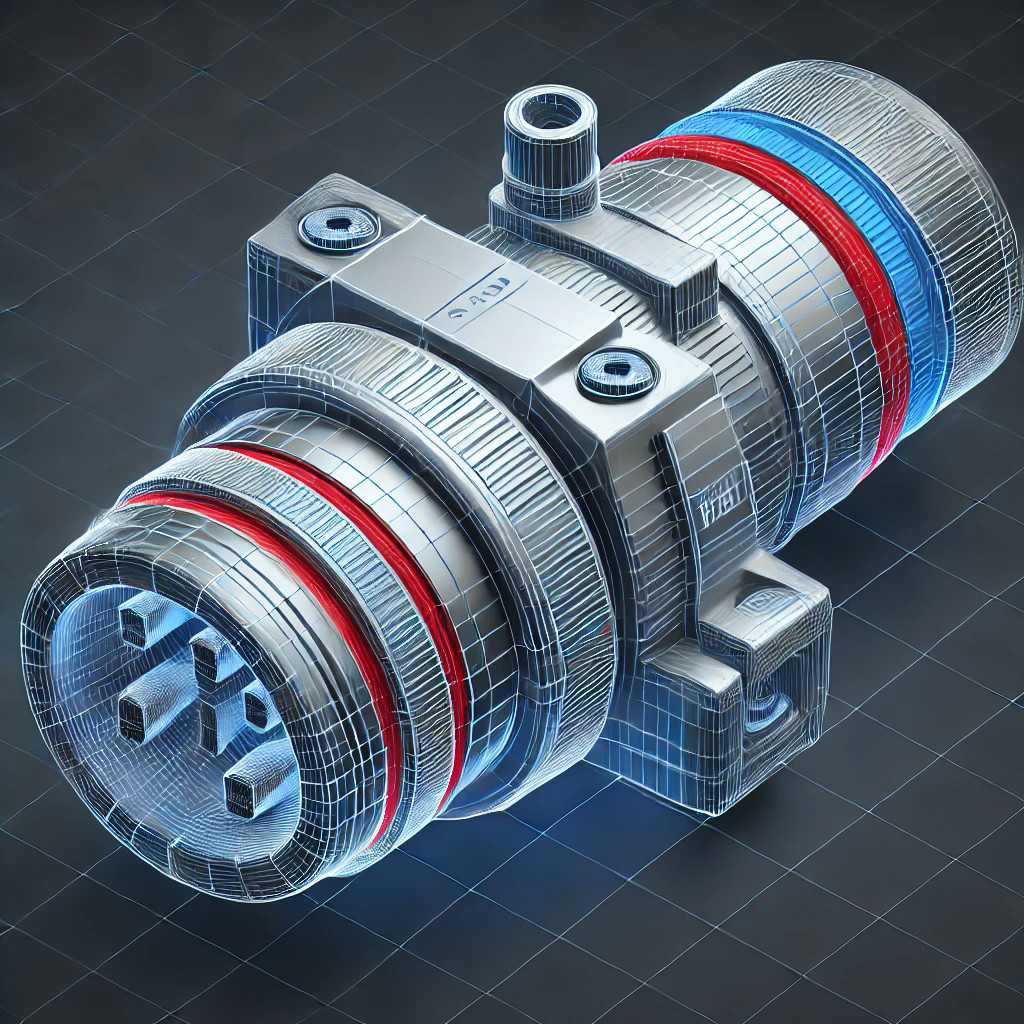

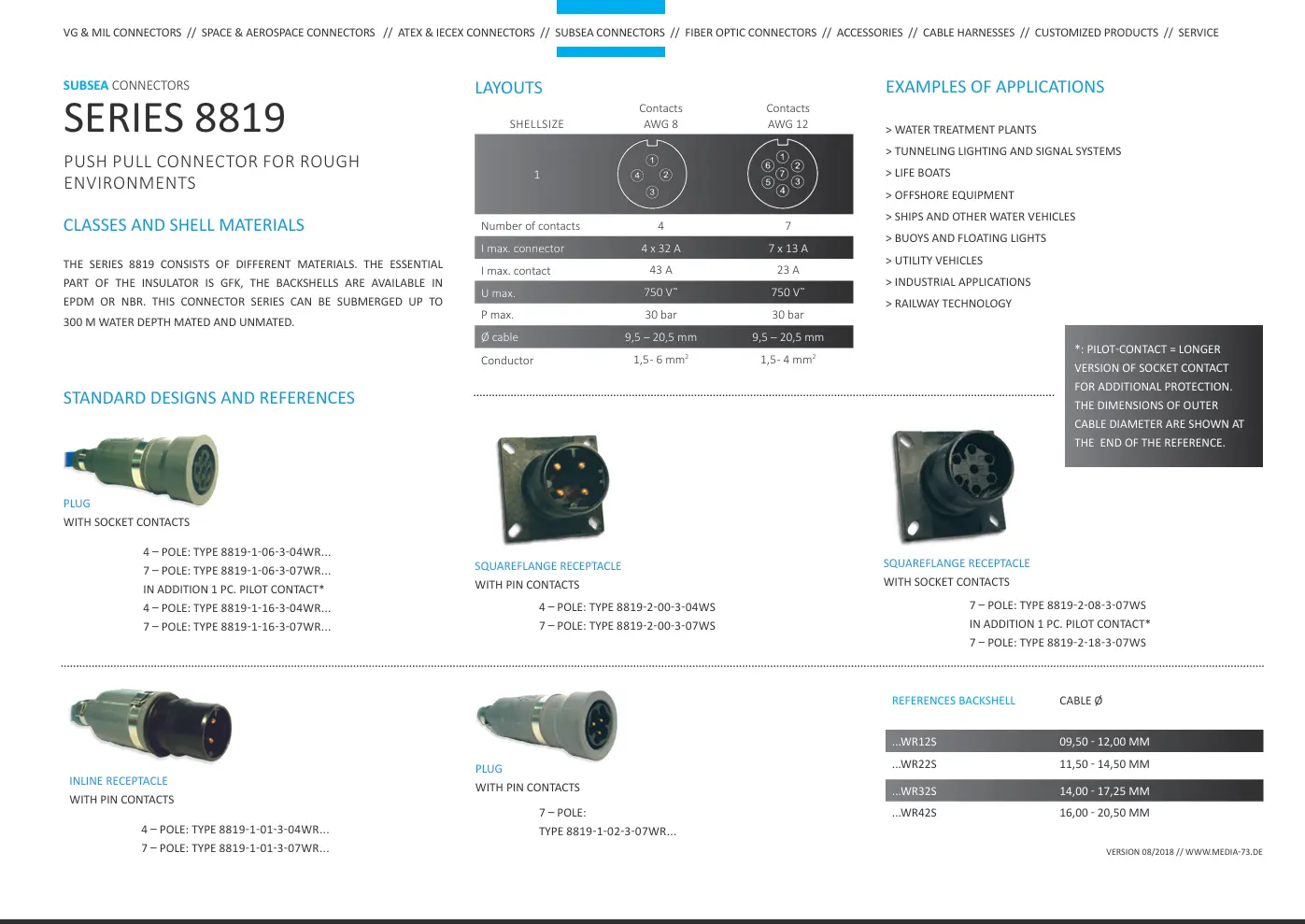

That’s not wishful thinking — it’s exactly what the JOWO 8819 underwater push-pull connector does. Engineered for submersion at 30 bar pressure (300m) in both mated and unmated conditions, this connector line is changing the game for ROV builders and offshore marine contractors.

One Flooded Connector Can Kill a Mission

Most subsea connector failures happen below the surface — literally.

Every deepwater operator has faced the nightmare: an ROV goes dark mid-mission, only to discover a failed or waterlogged connector caused the comms or power loss.

Traditional threaded or potted connectors aren't designed for quick disconnects, wet-mating, or the real pressure encountered at depth. They require epoxy, long cure times, and often fail at the worst possible moment — costing teams hours, sometimes days.

The consequences?

✔️ Lost dive windows

✔️ Emergency recovery

✔️ ROV damage or data loss

✔️ Thousands in wasted vessel time

Push-Pull and Pressure-Rated

is the New Baseline

ROVs are evolving. Their connectors should too.

The subsea industry is trending hard toward:

• Modular subsea hardware

• Swappable payloads and sensors

• Remote plug-and-play architecture

• Field-serviceable systems without epoxy curing

That means your connectors must now deliver:

• Quick-release operation (push-pull style)

• 300m+ depth waterproofing — even when unmated

• Compatibility with high data or power loads (up to 750V / 43A)

• ATEX/IECEx approval for use in explosive subsea atmospheres

It’s no longer acceptable to treat subsea connectors as “set-and-forget.” Modern systems demand hot-swap reliability, easy install, and watertight operation under dynamic pressures.

Upgrade Your Umbilical and Module Connectors

Start your next ROV upgrade with this checklist. Before your next dive, evaluate your current subsea connectors:

☑️ Is it a push-pull connector or an outdated threaded coupling?

☑️ Can it survive 300m open-face submersion (IP68 / 30 bar)?

☑️ Is potting required, or can it be serviced in the field without epoxy?

☑️ Does it offer ATEX/IECEx certification for flammable subsea zones?

If not, your crew is likely overpaying in downtime and risking preventable failure.

Download the whitepaper for the full Subsea Connector Upgrade Checklist.

JOWO 8819 - The Connector That Keeps Your ROV Online

What Dolphin Agencies learned at 300 meters might change how you spec your entire system.

Texas Electrical Connectors supplies the JOWO 8819 Series — a rugged, fully sealed underwater push-pull connector 300m rated, field-proven in deepwater applications from ROVs to underwater cameras and seafloor comms.

Key Features:

✅️ Push-pull coupling for fast, tool-free operation

✅️ No epoxy potting required – reduce assembly & service time

✅️ IP68 / 30 bar pressure rating even when unplugged

✅️ Available in 4-pin and 7-pin formats (up to 750V)

✅️ Certified for ATEX/IECEx explosive marine environments

✅️ Reinforced elastomeric seals and corrosion-proof polymer shells

Subsea Confidence from the Field

When a connector saves your mission at depth — you never go back.

Dolphin Agencies, a Florida-based marine contractor, recently upgraded their ROV umbilical and payload systems with JOWO 8819 connectors:

“We installed the 8819 on our subsea ROV comms gear, and the performance has been flawless. One unit was accidentally uncoupled at depth and reconnected — zero water ingress. Our tech said this connector might outlast the ROV itself.” – Operations Manager, Dolphin Agencies

Other benefits reported by Dolphin’s engineers:

✅️ Zero failures across 4 dives in 2 months

✅️ No epoxy needed — saved ~6 hours per cable

✅️ Improved post-dive inspection ratings

If your connector can't be trusted at 300 meters, it doesn’t belong on your mission-critical equipment.

The JOWO 8819 is designed for real-world use by real ROV operators, not lab conditions. The fact that it can be unplugged underwater with no leaks means it’s redefining what “subsea-grade” really means.

Marine contractors, ROV manufacturers, and subsea engineers:

If your mission relies on electrical continuity below the surface — this is the connector that has your back.

Engineered for depth. Trusted at sea. Available now.

🔹 $1000 Free USA Shipping

🔹 Download the Subsea White Paper