One Upgrade

Zero Failures

You won't believe how one connector upgrade helped eliminate electrical failures on a crude oil vessel operating in corrosive offshore conditions. The solution? An ATEX certified marine connector rated for open-face submersion up to 300 meters — no potting compound required.

Offshore Conditions Destroy Standard Connectors

Offshore oil operations deal with some of the harshest conditions in the industrial world — constant salt spray, high vibration, explosive atmospheres, and limited service windows. Connectors are often overlooked until they fail — and when they do, the costs add up fast:

☑️ Emergency shutdowns

☑️ Corroded terminals and arcing

☑️ Frequent drydock maintenance

☑️ Missed production targets

In many cases, standard marine connectors are not ATEX certified, cannot be serviced in the field, and degrade after just a few cycles.

Safety, Durability & Compliance

Over Cheap Imports

Regulatory bodies and internal safety standards are raising the bar.

Offshore vessels are now expected to use components with certifications like ATEX and IECEx for any areas exposed to vapor, heat, or pressure.

At the same time, marine engineers and procurement teams are shifting toward long-life, ruggedized infrastructure that reduces downtime and total life cycle cost.

This includes:

• IP68 or IP69-rated waterproofing

• ATEX certification for explosive environments

• Push-pull couplers for fast assembly and service

• Resistance to salt corrosion, UV exposure, and thermal fatigue

Audit Your Connectors

Before They Fail

Here’s a simple checklist you can apply today:

✅ Is your connector ATEX or IECEx certified?

✅ Does it require potting compound (if so, it’s not field-replaceable)?

✅ Can it survive 300m open-face submersion (rated IP68/30 bar)?

✅ Is it still performing after 1+ year in salt exposure?

If you answered “no” to any of the above — it may be time to upgrade.

• Download the rugged marine connector whitepaper for a full evaluation guide.

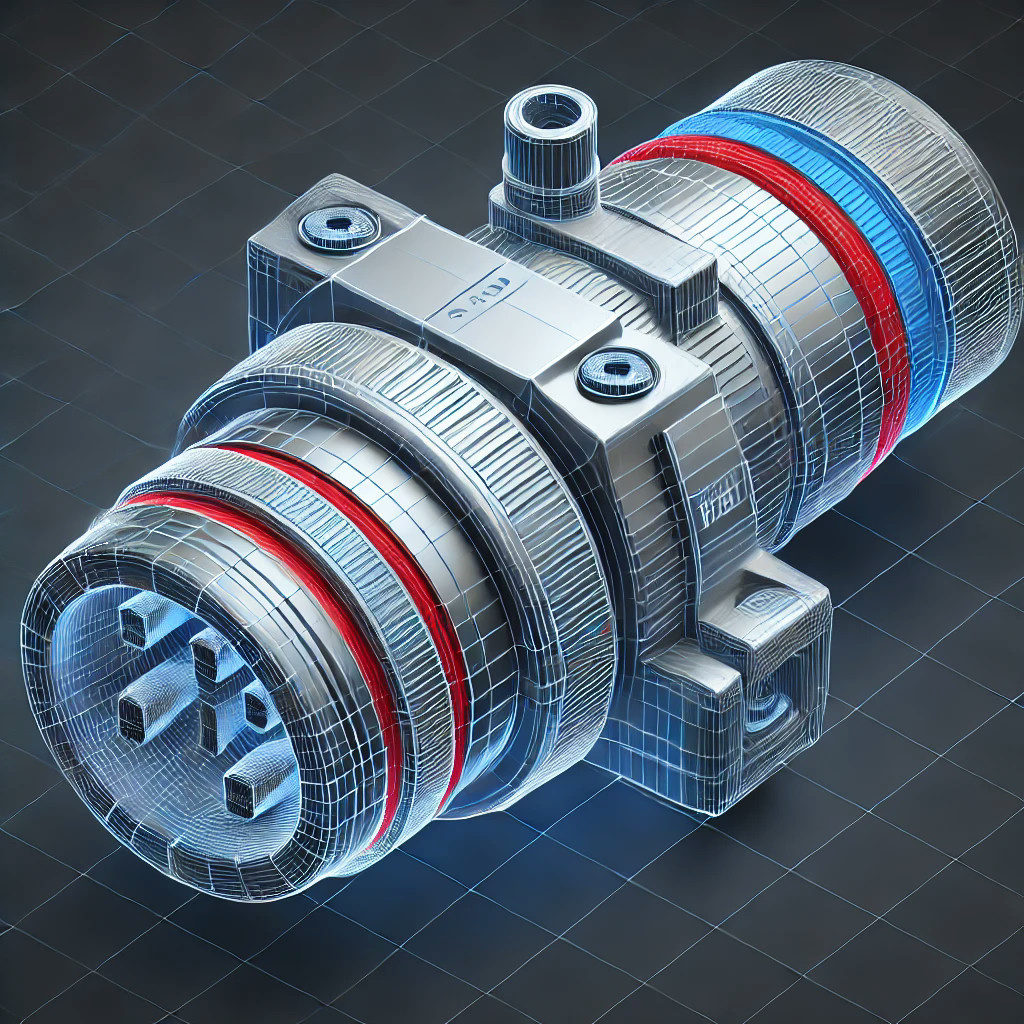

JOWO 8819

Certified for Offshore Toughness

Texas Electrical Connectors now supplies the JOWO 8819 Series, a premium push-pull marine connector line made in Germany and built for the realities of offshore life.

✔️ ATEX certified marine connector

✔️ 300m open-face pressure rating (30 bar)

✔️ Push-pull locking system (no threading)

✔️ No epoxy or potting needed

✔️ 750V / 43A contact support

✔️ 4 or 7 pin configurations

Chevron’s FLORIDA VOYAGER crude oil vessel was experiencing repeated electrical failures on deck lighting and pump systems. After retrofitting Fassmer life boats with the JOWO 8819 Series:

“Zero failures in two years — that’s the result after switching to the 8819. In the past, we’d replace corroded connectors every drydock cycle. Now our downtime is virtually nil.”

– Maintenance Superintendent, Chevron Shipping (FLORIDA VOYAGER)

Results You Can Point To

✅ In use by Chevron, Summit Electric, Manning Electric, and Dolphin Agencies

✅️ Ships from Houston with $1000 free U.S. shipping

✅️ Used in high-risk marine applications: pump systems, deck lighting, lifeboats

Future-proofing starts with your connection points.

Offshore engineers can cut failure rates, improve safety scores, and save thousands per year by standardizing on certified, modular connectors. If your connector isn’t built to survive your worst day at sea — it’s the wrong one.

Ready to stop replacing connectors every drydock? Let’s talk.

🔹 $1000 Free USA Shipping on Your First Order